Dairy

Boost Autonomous Maintenance in your factory.

Maintain the high standards and processes within your factory by auditing regularly

Auditing for compliancy and continuous improvement

Compliance with standards, laws, rules and guidelines, both internally and externally imposed by the internal organization, government or other external organizations, is not easy to organize on paper.

Assurance and compliance can be organized in a simple and digital way. This ensures that everything is available in a visual and standardized way for every discipline to comply with all rules and guidelines. Furthermore, the current standard can be improved continuously.

The EZ-GO platform enables different disciplines within factories to regularly monitor and audit procedures and processes to maintain standards.

Safety and Hygiene rounds

Ensure the safety and hygiene within your production environment by executing frequent checks

Multidisciplinary use

Audits are being used for example by Production, QESH, HR, and Maintenance

Pending actions

Simple overview in which tasks still need to be executed from pending actions

Increase involvement

100% execution of the standards and be king in Continuous Improvement

Instant chat module

Use the chat module to communicate with all your colleagues concerning improvements or problems

Action management

Simply add text, images and video’s to audit items to communicate improvements

View history

Look back in time with reports and find out if any improvements can be made

Score method

Audits can be configured in many ways by changing the scoring method

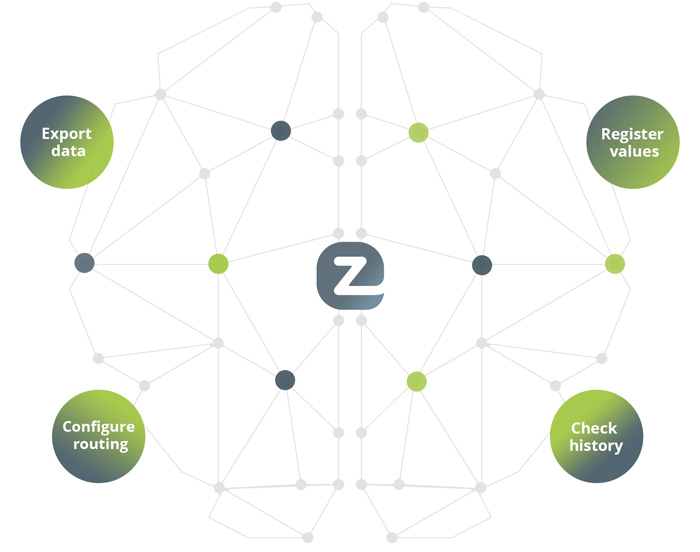

The platform offers, next to a mobile version, also a web portal where authorized users can upload information, check reports, export data and configure the entire platform.

Other manufacturers have preceded you in the digital transformation of their production environment and already experience benefits of the EZ-GO platform.

Boost Autonomous Maintenance in your factory.

Maintain high standards within your production environment.

Sustain quality of products.

More focus on control and cleanliness, resulting in better safety for employees.

Improved productivity and educate operators easier.