Dairy

Boost Autonomous Maintenance in your factory.

Involved and well-trained factory workers who show ownership, enable growth to a world-class level in safety, quality and efficiency

The aging population and the high turnover of employees have an enormous impact on safety within a factory and the performance of a factory.

Therefore, safeguard knowledge and skills within the factory with clear visual work instructions and ensure that everyone can work safely and, when necessary, there is always a standard work procedure that can be used immediately.

The EZ-GO platform enables operators to always have the most recent work instructions available, stimulates continuous improvement and ensures better performance in the workplace.

Directly accessible

Capture, transfer and real-time accessibility of specific knowledge from experienced operators

One platform which provides overview in

WHAT to do, WHY to do it, WHEN to do it, HOW to do it

Visualize

Use videos to express even better how important procedures should be executed

Increase involvement

Adjust work instructions immediately based on feedback from the production floor

Build a skill matrix

Get insight in the skills of employees

Continuous Improvement

Motivate operators to continuously improve standards and work instructions

Mobile access

Operators use mobile apps to access the latest work instructions

Workplace training

Easily build visual and standardized work methods & procedures in a workplace training area

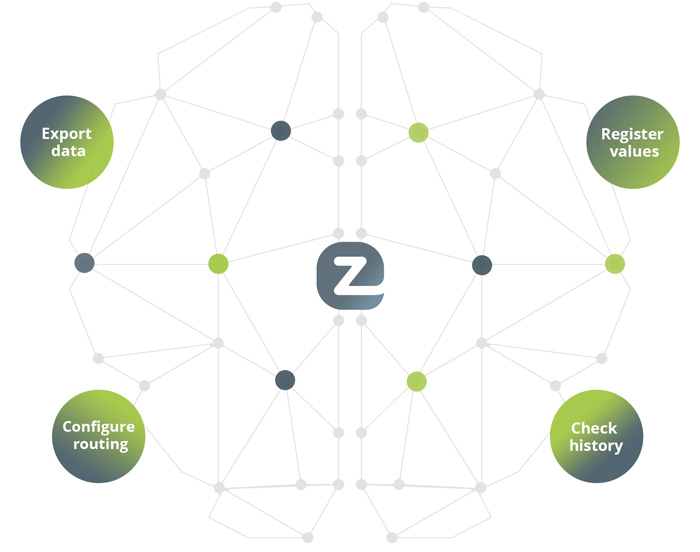

The platform offers, next to a mobile version, also a web portal where authorized users can upload information, check reports, export data and configure the entire platform.

Other manufacturers have preceded you in the digital transformation of their production environment and already experience benefits of the EZ-GO platform.

Boost Autonomous Maintenance in your factory.

Maintain high standards within your production environment.

Sustain quality of products.

More focus on control and cleanliness, resulting in better safety for employees.

Improved productivity and educate operators easier.