Dairy

Boost Autonomous Maintenance in your factory.

Plan recurring Autonomous Maintenance tasks and support operators, team leaders and managers to guarantee the basic condition of the factory by digitizing standards in an easy way.

The daily activities of a factory worker have an enormous impact on the end consumer.

Maintain and control the basic condition of your factory with task management and make sure that end consumers can safely enjoy the manufactured quality products.

The EZ-GO platform provides factory workers overview in which, how and when Autonomous Maintenance tasks concerning cleaning, inspections and lubrication should be executed. This keeps the production line in good condition and reduces safety incidents, planned downtime, waste and improves productivity.

Real-time overview

Every operator has real-time overview in all relevant Autonomous Maintenance tasks

Autonomous Maintenance planning

The EZ-GO platform plans Autonomous Maintenance, so only necessary cleaning-, inspection- and lubrication tasks are executed

“On the Spot” work instructions

Work instructions are ”on the spot” available for a visualization of standard operating procedures (SOP)

Clearly visual

Tasks are clarified with the use of images, video’s and work instructions

Simply duplicate best practices

Autonomous Maintenance tasks can be simply duplicated and applied to similar production lines

Area structure

EZ-GO is structured in existing production lines, work areas and machines

Management and escalation

Work towards 100% implementation of Autonomous Maintenance Tasks and immediately escalate in case of deviations by reporting an action

Plan- Do- Check- Act Reports

Always up-to-date about the status of planned work and the biggest deviations found in the production environment

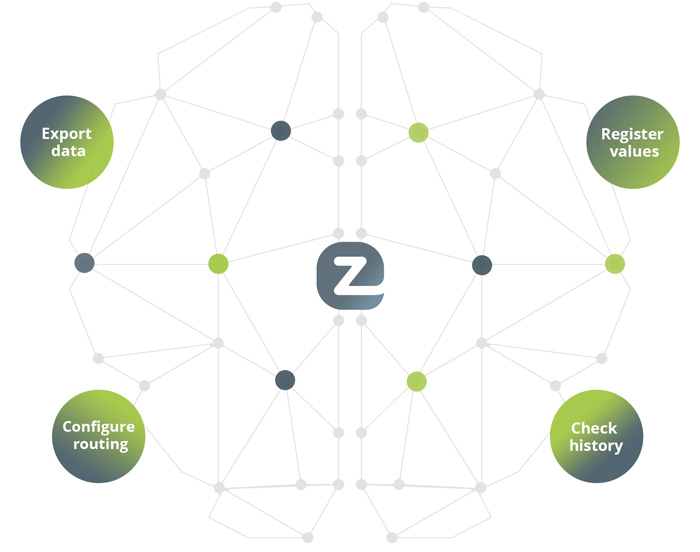

The platform offers, next to a mobile version, also a web portal where authorized users can upload information, check reports, export data and configure the entire platform.

Other manufacturers have preceded you in the digital transformation of their production environment and already experience benefits of the EZ-GO platform.

Boost Autonomous Maintenance in your factory.

Maintain high standards within your production environment.

Sustain quality of products.

More focus on control and cleanliness, resulting in better safety for employees.

Improved productivity and educate operators easier.