When we talk about achieving an efficient production process, shortening the lead time becomes an…

Preventive maintenance is planned and executed to improve the reliability of factories, installations and machinery to prevent damages, downtime, errors and other issues during production time.

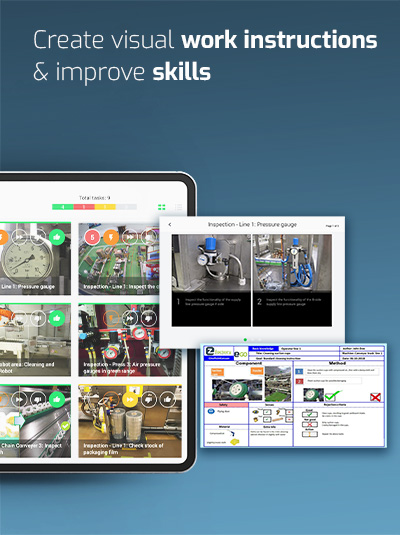

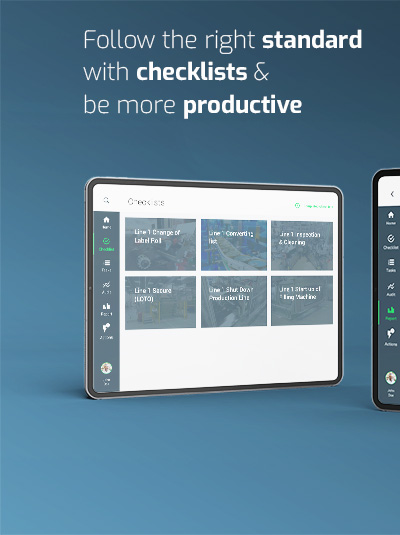

The activities are performed according to a fixed maintenance schedule. With the EZ-GO app from EZ Factory, employee ownership is linked to the machines with which they work every day. This can also be called autonomous maintenance or firstline maintenance. This results in a greater sense of responsibility for the production machines. Preventive maintenance leads to more knowledge and expertise among production employees regarding the machines, a higher reliable output, ownership based on knowledge and skills and a higher satisfaction and motivation among production employees.