Optimizing a production or business process using lean principles can be highly beneficial for your…

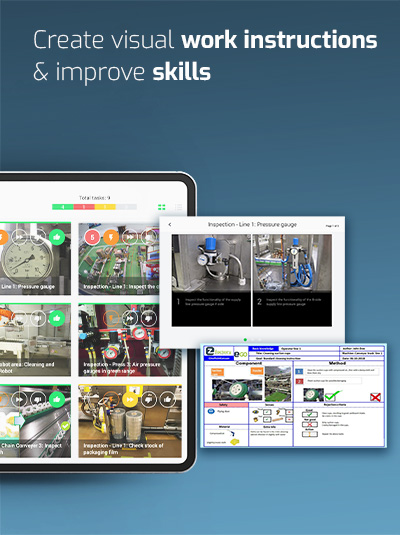

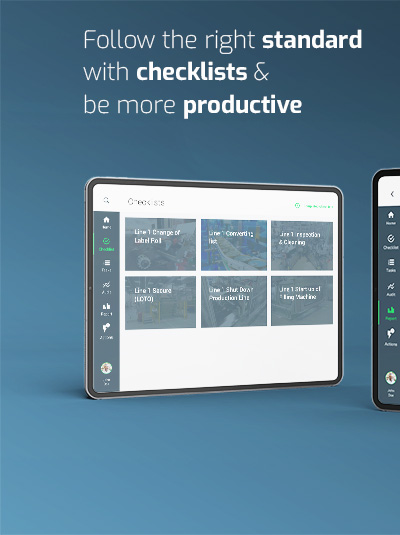

Structurally conducting mobile inspections are important for maintaining production lines in optimal condition. The need to create digital checklists and tasks for inspecting machines and equipment and sharing operating procedures is ever important in the daily work of operators. Mobile inspections are a powerful and digital tool which enables operators to inspect more efficiently. EZ Factory’s EZ-GO mobile inspections app empowers your personnel to conduct inspections autonomously and continuously improves processes in your factory. Many companies work with our mobile inspections app, including FrieslandCampina and Jacobs Douwe Egberts.