Statistical Process Control has been used since the 1980s to monitor processes statistically. Especially within…

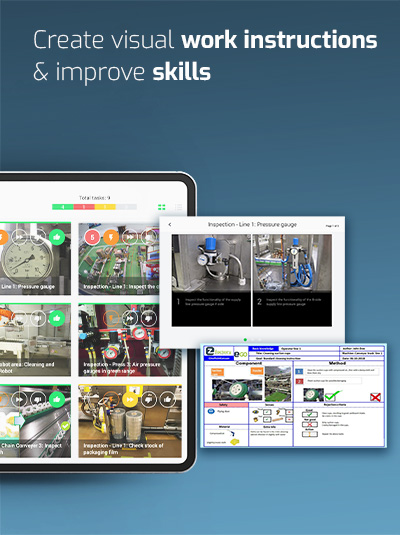

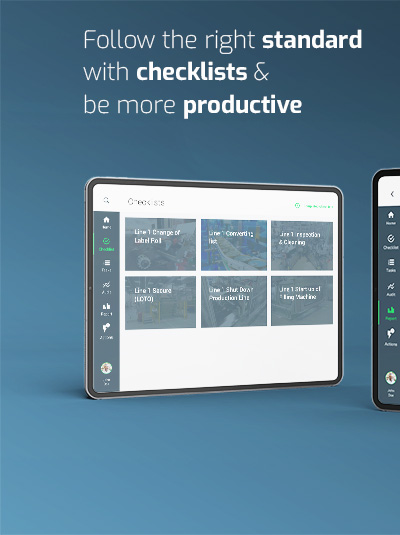

Continuous improvement software enables you to continuously improve key processes and procedures within your factory. By keeping track of where in processes a weak link occurs and act on it, you can turn your factory into a work environment that constantly keeps improving. Another advantage of using Continuous Improvement software is that your machines and equipment have a lower chance of unplanned downtime or major quality issues. EZ Factory’s EZ-GO mobile app allows operators to work independently and continuously improve processes in their daily work.