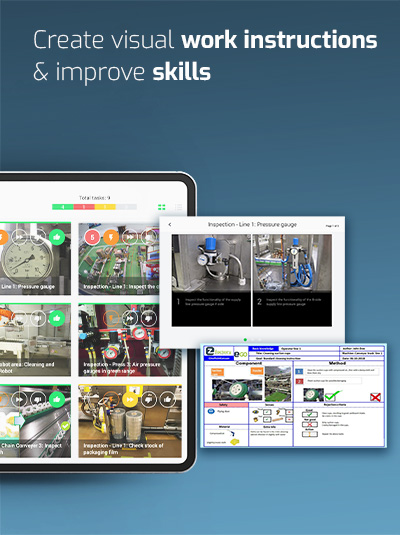

By digitizing a SOP or working instruction, the operator always has them at hand in the form of the EZ-GO app on a smart device. As a result, he is able to work much more efficiently, and he will also be more inclined to take it with him if he needs the reference book when performing an operation in the right way.

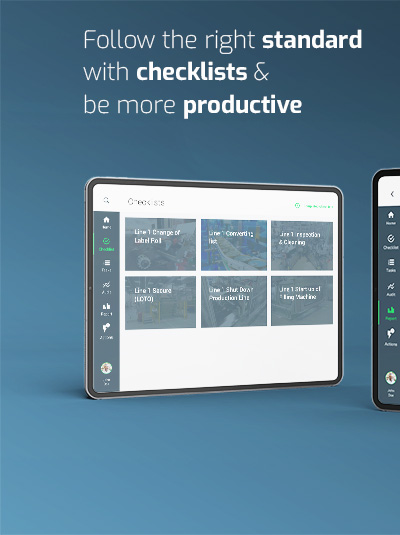

To make the day-to-day work of operators clearer and more fun, we have developed an app for digitizing work instructions, checklists, autonomous maintenance tasks and audits. This allows the safety, quality and efficiency on the shop floor to be increased. Digitizing SOPs will reduce the number of unexpected failures, increase the availability of your machines, ensure quality and extend the life of your machines. This prevents unnecessary revenue loss and disappoints customers.

When you log in to the app, you’ll see at a glance what your core tasks will be for that day. This increases safety, quality and efficiency. What is unique about EZ-GO is that we focus on the operator. Our slogan is: “Power to the Operator!” After all, this is the man or woman in the workplace who performs the tasks and can identify where and how processes can be optimized. Our goal is therefore to make their daily work easier and more enjoyable!